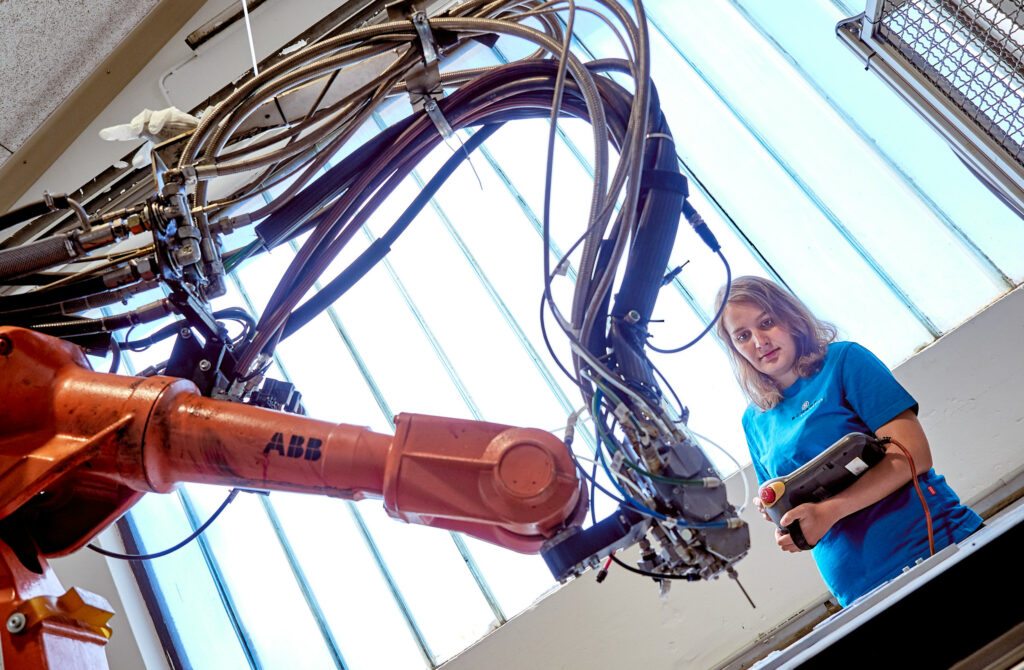

Start the digital transformation of your company! We provide a full range of services, comprehensive advice, ideally adapted software, PLCs, robotics and simulations. We help with implementation, ongoing operation and also take care of service and maintenance.

You will benefit from:

-

Increase in productivity

-

Cost saving

-

Greater operational safety by avoiding errors, failures, downtimes and the risk of accidents

-

Increased functional safety through documentation, testability, inspection accuracy

-

More flexibility

Our solutions in detail::

PROGRAMMING OF CONTROLLERS

–

Innovations and new control systems are changing entire industries at a rapid pace. To keep you up to date, Scharf Automation will guide you safely through the world of digitalisation and offer you the following benefits:

-

Efficient training: As soon as the machine is ready, the machine operators will receive excellent training from us.

-

Expert know-how: You save on lengthy, expensive training for your staff and can get started straight away.

-

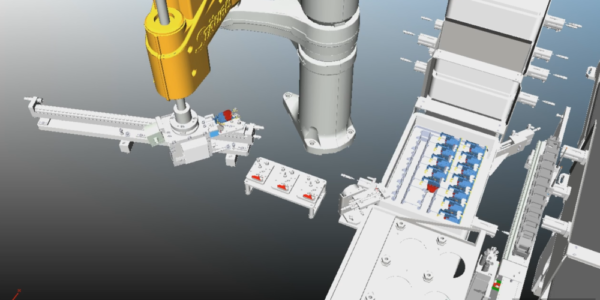

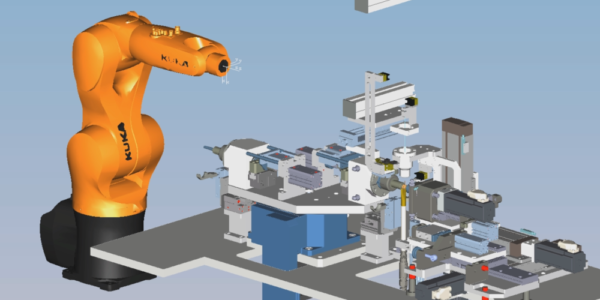

Digital twin: In addition, we offer virtual commissioning of the control system, which brings numerous advantages.

-

Many years of experience: We have been working for many years in the programming of controllers from different manufacturers – such as Siemens, Vipa, B&R and Beckhoff.